With a proven track record covering more than twenty years, TFL has evolved to become the market leader for the supply of quality welded tubes and cylinders, manufactured specifically to individual customer requirements. Your business can rest assured that in TFL it has a supplier who can cope with the most arduous of tasks and is flexible enough to adjust to your specifications and needs.

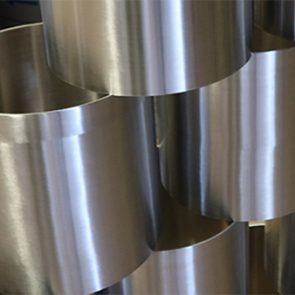

TFL have the in house skills to produce automatically or manually welded tubes and cylinders in a variety of exotic materials, including Titanium, Nickel, Hasteloy and all their associated alloys.

The complete range of Stainless Steel and Stainless Steel alloys are common to tubes and cylinders produced by TFL.

A wide range of Aluminium (>125mm wall thickness) and copper (>25mm wall thickness) tubes and cylinders are just two of the exotic materials being welded to the highest specifications regularly at TFL.

With a diameter range of 10mm>2500mm, a length range >2500mm (longer lengths can be achieved by means of circumferential joins in some circumstances) and a wall thickness range of 0.25mm > 125mm, TFL should be able to cater for most needs.

Working with TFL as part of your team in a ‘business partnership’ has its reward. Integration with customers is vital, as it enables TFL to develop an understanding of your products and their usage and with TFL striving for continuous improvement, ensure the ongoing quality and suitability of product at a cost effective price.